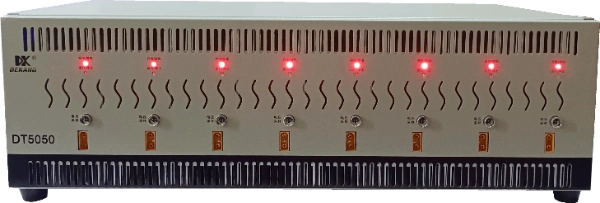

5V 50A Lithium Battery Cell Capacity Grading Electric Car Traction Lithium Battery Pack Balance Maintenance Auto Cycle Charge and Discharge Equalizer Tester

Description:Lithium Battery Auto Cycle Charge Discharge Tester DT5050 can be used for the capacity test, charge characte

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | DT5050 |

| Application 2 | Li-ion Battery Assembly Capacity Grading |

| Application 3 | Lithium Battery Pack Balance Maintenance |

| Application 1 | Lithium Battery Production Aging Test |

| Description | Lithium Battery Sorter, Battery Balancer |

| Approval | CE |

| Quality Management System | ISO9001 |

| Software Customization | Available |

| Application 4 | Lithium Cell Quality Control and Inspection |

| Min. Charge Cut-off Current | 0.05A |

| Software Languages | English |

| Max. Charge & Discharge Current | 50A |

| Applied Battery | Lithium Cell <5V, <300ah |

| Channel No. | 8 Channels |

| Transport Package | Seaworthy Packing |

| Specification | 675*340*235 mm |

| Trademark | DK |

| Origin | China |

| HS Code | 9030409000 |

| Production Capacity | 5000 Pieces/Year |

Product Description

Description:Lithium Battery Auto Cycle Charge Discharge Tester DT5050 can be used for the capacity test, charge characteristic test, capacity grading and matching, balance maintenance, and internal resistance test of various types of Li-ion Batteries, Ni-MH Batteries, and Ni-CD batteries. It can be compatible with cylindrical, pouch, and prismatic cells. The isolation channel testing design can determine the location of the defective cells without disassembling the battery pack. Each channel is configured with a separate processor which can independently charge and discharge the battery, maintain the balance of the battery pack, and restore the unbalanced battery pack to a normal balance level.It's suitable for large lithium battery testing, maintenance, battery pack assembly and EV battery repair, etc.

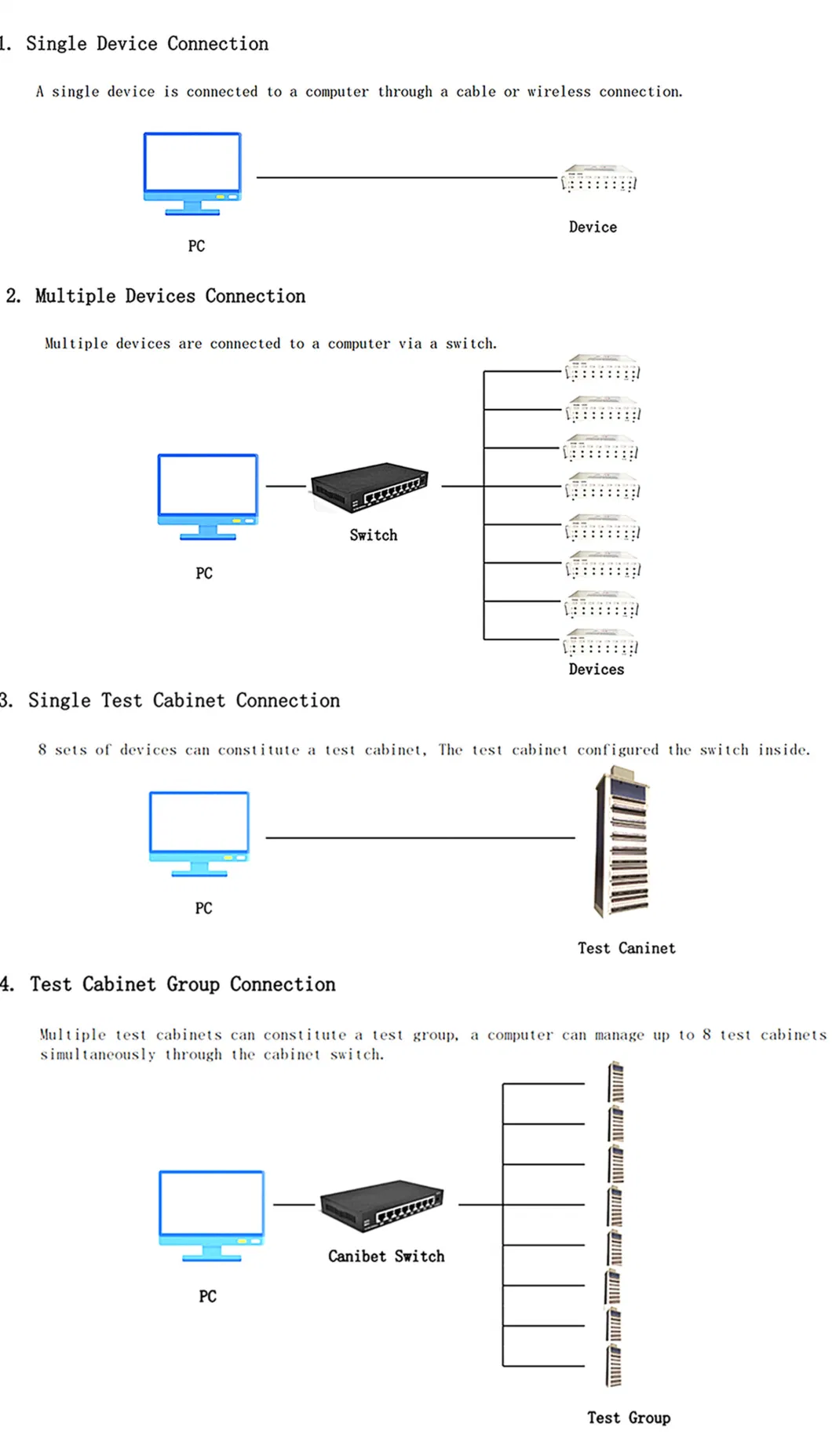

DT5050-64 is composed of the single DT5050, a number of DT50W-64 can constitute a testing group to match the needs of mass testing.

Lithium Cell Capacity Grading and matching Test SystemDT5050-64

Applicable Batteries:

Features:• Each channel is equipped with a dedicated processor to ensure a perfect level of capacity calculation, timing, voltage and current control.• All channels are under isolated test; it can directly test the cells of the battery pack.• Independent heat source channel, temperature control and speed regulation fan.• The LED light indicates the running status, testing status, matching status, alarm status.• Fully compatible with the batteries of Li-ion, Polymer, Ni-MH, NiCd, and so on.• Fully compatible installation with cylindrical, pouch, prismatic batteries.• Online test between computer and device, the setting and results is particular and plentiful,• With the work steps of Constant Current Discharge, Constant Power Discharge, Constant Resistance Discharge, Constant Current Charge, Constant Voltage Charge, Constant Current & Voltage Charge, Internal Resistance Test and Idle, etc.• Work step automatically switching.• The charge and discharge parameters can be customized.• The matching can be processed, the test results can be matched according to the customized standard, and it can mark and display on the device. • The recording function of the test process• With 3 Y-axis (voltage, current, capacity) and a time axis curve drawing ability, and data report function. • The color of the test status bar is customized, which makes it easy to check the test status of all devices when the number of tests is large.

• The battery temperature monitoring and control management system can be installed upon request to realize safe unattended charging.

Technical Specification

| Model No.: DT5050 | ||

| Input Voltage: | AC 220V± 10% 50Hz/60Hz | |

| Input Power: | No-load 80W, full load 1650W | |

| Voltage | Max. Charge Constant Voltage: | 5V |

| Min. Discharge Cut-off Voltage: | 1V | |

| Tolerance: | 0.02V | |

| Current | Max. Charge Current: | 50A |

| Max. Discharge Current: | 50A | |

| Min. Charge Cut-off Current | 0.05A | |

| Tolerance: | 0.02A | |

| Power | Max. Output Power (Single Channel) | 200W |

| Data Recording | Data Recording Conditions | Time interval |

| Voltage interval | ||

| Current interval | ||

| Charge | Charge Modes: | Constant current charge |

| Constant voltage charge | ||

| Constant current & voltage charge | ||

| Charge Cut-off Conditions: | Voltage, current, time, capacity, -△V | |

| Discharge | Discharge Modes: | Constant current discharge |

| Constant power discharge | ||

| Constant resistance discharge | ||

| Discharge Cut-off Conditions: | Voltage, current, time, capacity | |

| Cycle | Cycle Index: | 1-5000 times |

| Protection | Power-down protection | |

| Reverse connection | ||

| Over-temperature protection | ||

| Over-voltage protection | ||

| Short-circuit protection | ||

| Expand functionality | Battery temperature monitoring and control system | |

| IP Grade | IP20 | |

| Channel Control Mode | Independent control | |

| High Voltage Insulation Between Channels | AC1000V/2min Normal | |

| Voltage & Current Test Sampling | 4 core wires connection | |

| Noise | < 76 dB | |

| Host Computer Communication Method | based on TCP/IP protocol | |

| Test Report Output Method | Excel | |

| Server Disk Configuration | >100GB | |

| Server Operation System | Windows XP, Windows 7/8/10 | |

| Communication Port | LAN | |

| Equipment Work Ambient Conditions | ||

| Operation Ambient Temperature | 0 ºC - 40 ºC | |

| Storage Temperature | -10 ºC - 50 ºC | |

| Operation Ambient Humidity | ≤ 70 % RH (No condensation) | |

| Storage Ambient Humidity | ≤ 80 % RH (No condensation) | |

Illustrations:

Packing Information:Produce Size: 67.5*34*23.5cm(L*W*H)Pcs/Ctn: 1 pc/ctnPackage Size: 77*46*29.5 cm(L*W*H)G.W.: 25.60 kgsN.W.: 23.60 kgs

Battery Connection

1. Applicable Batteries:

The DT5050 supports batteries with voltage <5V and capacity < 300AH, in the physical specification, it supports cylindrical, pouch, and prismatic batteries.

2. The connection of the pouch cells & prismatic cells

Connect the positive and negative poles of the battery with the alligator clip output cable (

Different clamp styles are customizable for different battery polarity structures).

3. The connection of The Battery Pack Balance Maintenance

Connect the positive and negative poles of each string with the alligator clip output cable (

Different clamp styles are customizable for different battery polarity structures).

.

Schematic Diagram of Upper Computer Connection

About us:

Founded in 2005, DEKANG is a high-tech enterprise involved in researching & development, production and sales of Storage Battery Measuring & Maintenance Equipment, EV Charging Station, Shared Power Swapping Station, Shared Mobility Solution. We provide the clients with the complete solution of storage battery service.

Products Category:

Battery Charging & Discharging TesterBattery Testing and Recovery EquipmentLithium Battery Intelligent ChargerE-Bike/E-scooter Charging StationShared Battery Charging & Swapping SystemIntelligent Lithium BatteriesBattery-swapping E-bike/E-scooter and so on.

Why choose us?

- Beginning from 2005, we have achieved the leadership of our industrial

- Over 15 years of experiences

- Powerful function and superior performance

- Professional and strong R&D team.

- Technical leadership and advantage

- Advanced production technology and automatic assembly line

- Market verification and specialized users approval from over 50 countries

- Rich experience in market operation

- Professional after-sale service, lifelong after-sale service provided

Sample order dispatched by express via DHL, FEDEX,TNT,UPS or any other express services you prefer to, also we can coordinate to send it to other agreed address in China for loading with your convenienceNormal order delivered by sea or air as per your instructions.

Equipment operation training & guidance

In addition to providing user manual and operation videos, after you purchase the equipment, we will also provide operation training and guidance support through telephone, email, video connection, remote connection and other ways, so as to ensure that you are proficient in the operation and use of the equipment. Our equipment is intelligent in design, rich in functions and easy to operate. Make it easy for you to operate.

Warranty:

12-month warranty, lifelong after-sale service and free technology service.

After-sales service

Very important: the DK exporting division is the only official exporting department of DK INTELLIGENT. Anyone who obtains our equipment from a third party or through other channels may have the risk of not being able to obtain official after-sales & technology service. In order to ensure that you get official service and technical support after purchasing the product, overseas users please purchase the products directly from the official exporting department of DK INTELLIGENT or our local authorized distributor.

.

Free replacement parts will be provided during the warranty period, and we will dispatch the replacement parts to the user by DHL, UPS, TNT or FEDEX at our account and guide the user to replace via phone, email or video. The modular design of our equipment makes it easy to install and replace

After the warranty period, the cost of replacement parts will be charged. If you pay for the replacement parts, you can enjoy a free warranty within half a year from the maintenance date for the same problem.Lifelong free technology service provided by us, the users can advise malfunction and inquire the maintenance technology through the telephone, fax, email, and social media, etc.Paid service The conditions below are not included in the free maintenance range, the company provide the paid service, kindly note:

- Do not operate or use as per the manual and cause the damage

- The instrument was disassembled or repaired by the non-authorized person by our company

- Unexpected factors or man-made causes the damage, such as the water inflowing, mechanical damage, falling, burning and so on.